Statistically said, it is generally known that 30% of recorded 100% of building fires arises and is propagated via cable routes, thus cables and cable routes represent a line element of buildings through which fire can be transferred to all building zones. At the same time, as almost all cables are built into buildings, they fall under CPR (Construct Product Regulation) requirements. The basic requirements for the safety of buildings in terms of European law are governed by Regulation (EU) No. 305/2011 of the European Parliament and of the Council of 9 March 2011, laying down harmonised conditions for the marketing of construction products on the EU market and defining a common classification of construction products, thereby aiming to increase safety in buildings. Under the new regulations, the following features are generally required for cables and electrical installations for selected sections of buildings: fire safety, hygiene, health and the environment. These features need to be demonstated by extensive certification system, in order to ensure only approved products usage on construction sites.

In 2011, a new EN 50399 was adopted, allowing the evaluation of reaction to fire of the cables for the classes Aca, B1ca, B2ca, Cca and Dca. The "Reaction to fire" property has been defined only for cables with increased resistance to flame propagation (with no requirements for functional resistance of cable routing in the event of a fire) by the harmonized European Standard EN 50575 in 2014, which describes which cable properties are classified in the event of a fire, determines the extent of classification for particular classes, refers to test methods and imposes obligations for the quality of the cables in the market on responsible authorities. It orders the manufacturer to test each cable installed in construction project and categories it within one of the following fire reaction classes: Aca, B1ca, B2ca, Cca, Dca, Eca and Fca.

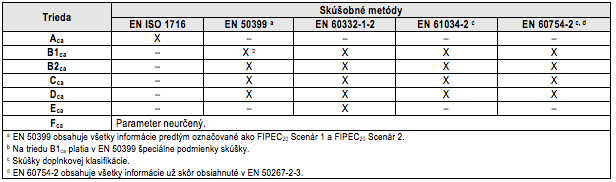

Test requirements for each category are as follows:

These requirements are amended by the following additional classification: smoke production (smoke, s), flaming droplets (drops, d) and acidity of gasses (halogen-free) occurring during burning (acidity, a), being classified into the following categories:

d0 no flaming droplets during test

d1 flaming droplets go out 10 seconds after dropping

d2 no parameter warranty

s1 light intensity of smoke production (s1a – very light intensity of smoke spread, s1b – light intensity of smoke spread)

s2 average smoke production and smoke spread

s3 no parameter warranty

a1 very low acidity

a2 low acidity

a3 no parameter warranty

If we try to compare the development of cable safety requirements abroad and in Slovakia, we can say that Slovakia and the Czech Republic are among the leaders in this area, as there ha sbeen valid legislation for several years before the adoption of the regulation and the harmonized European standard EN 50575. The cables for selected electrical wiring shall comply with the requirements of Regulation no. 305/2011 for reaction to fire for classes B2ca and B2ca s1d1, being included in the Czech legislation(Decree No. 23/2008 Coll., Or its amendment - Decree 268/2011 Coll. of 12.09.2011).

The Slovak Republic falls under the legislation, defined by the Law No. 133/2013 Coll.on construction products and the related Decree of the Ministry of Transport, Construction and Regional Development of the Slovak Republic No. 162/2013 Coll., whereas particular sections are described in STN 92 0203, Annex B.

The cable requirement of Annex B of the regulation is as follows:

Reaction to fire class and additional classifications:

B2ca – a cable burning test in a bundle where the total amount of heat released from the cables represents the value 1 200 s ≤ 15 MJ; the highest heat release rate represents ≤ 30 kW, flame spread ≤ 1,5 m; fire development rate ≤ 50 Ws-1;

s1 - total smoke production represents TSP1200 ≤ 50 m2 and immediate smoke release rate ≤ 0,25 m2 / s;

d1 - no burning droplets / particles lasting for more than 10s for 1 200s;

a1 - conductivity <2.5 μS / mm and pH> 4,3 in accordance with EN 60754-2.

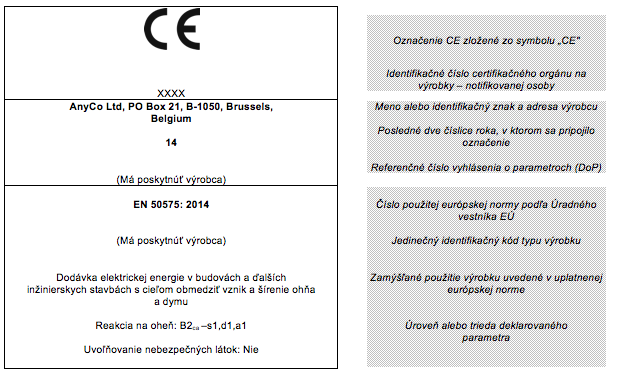

Essential data on cables as construction products are on the cable tags, as well as within their description on the cable sheath. Cable tags meeting the requirements for B2ca category of EN 50575 must include the following data:

Obligations of CPR for manufacturers:

Manufacturers are responsible for assessing the parameters of their products according to the requirements of the legislation. They shall draw up a declaration of non-conformity of the construction product parameters in accordance with the requirements of EN 50575. Manufacturers shall, on the basis of the Declaration of Performance (DoP) draw up a technical documentation describing all relevant elements relating to the required system for assessing and verifying the stability of the parameters. This documentation is kept for 10 years. Manufacturers shall ensure that procedures are in place to ensure that the declared parameters are maintained in mass production. They are responsible for identifying and marking each cable packaging with their contact details. The recommended marking of the cables is as follows: B2ca fire reaction class, including any additional classifications shall always be indicated on the tags and directly in the printing on the cable sheath along with the CE marking. For other (lower) fire reaction classes (Cca, Dca, Eca, Fca) it is sufficient enough to indicate the information on the cable tag, in accordance with EN 50575.

Obligations of CPR for designers:

Designers shall define appropriate cabling with a corresponding class of reaction to fire according to the valid legislation and fire design of the building in the construction projects for each building space. They must take into account the fact that no cables in the lower class classification of fire reaction than prescribed for the given construction section shall be installed when designing cableways.

Obligations of CPR for importers:

Importers place on the EU market only construction products that comply with the relevant requirements of EU Regulation No. 305/2011. They demand the same acts, commitments and documentation from their suppliers as are applied to EU producers. Importers ensure the identification of the cables, marking each cable packaging with their contact details (not the manufacturer), thus taking responsibility for product safety and capability on the EU market.

Obligations of CPR for distributors and sellers:

When introducing a construction product on EU markets, distributors shall take due care with regard to the requirements of EU Regulation No. 305/2011. By taking products to distribution or sales, they take responsibility for meeting the requirements of this Regulation against the customer. When dividing the cable supplied by the manufacturer or importer, distributors are required to ensure continuity for each cable length in order to identify its marking on all the parts distributed.